UV curable resins & formulated products market is propelled by the innovative formulations in coating applications

UV curable resin is an experimental product that reduces air pollution and energy consumption. Increasing necessity for the reduction in energy-consumption is leading to prominence of UV curable resins, especially in the contemporary coating industry. It is creating a significant opportunity for the energy-curable resin producers to increase their UV-curable resins market share. Therefore, this resin is primarily used in diverse applications of the ink, adhesive, and coating industries. This is because of their high productivity, ease of application, and low impact of UV curable resin on the environment. They have become an ideal choice when fast drying and curing is needed because these resins have excellent chemical resistance and faster curing rates compared to conventional drying techniques. In the inks industry, this resin is mostly applied for UV flexo, lithographic printing, overprint varnishes, screen, optical fibers, and as a part of encapsulation and potting in various electronic elements such as sensors, capacitors, connectors, switches, inductors, and relays. Additionally, concrete, plastic coatings, scratch-resistant wood, and UV curable acrylic adhesives are some of the other important applications of UV curable resins. In addition to this, less volatile organic compound (VOC) emission regulations and standards are strengthening the demand for low VOC coatings. Therefore, UV curable resins are highly accepted as they provide low thermal stressing on substrates, high scratch, and chemical resistance, and decrease the use of VOC.

The global UV curable resins & formulated products market size was evaluated at $4.1 billion in 2018, set to grow with a CAGR of 10% throughout the forecast period 2019-2025.

The Predominance of Coatings Application in the UV Curable Resins & Formulated Products Market:

Epoxy acrylates, polyester acrylates, aliphatic urethane acrylate, and aromatic urethane acrylate are the key acrylate oligomers in use today. The growing prevalence of wood & paper, plastic, and metal coating application is leading to growth of the UV curable resins market size. Thus, coatings application is identified as the fastest-growing among overprint varnishes, printing inks, adhesives, and 3D printing applications, and it is set to grow at a CAGR of 5% over the forecast period. Novel properties of UV-curable resins such as improved outdoor resistance along with notable adhesion on metals and plastics are aiding for the growth of new waterborne UV-curable coatings in the global UV curable resins market. In this contemporary world, architectural and decorative coatings are gaining traction of consumers. This is because it has become an ideal choice for interior wall coatings at schools and hospitals. Waterborne coatings have become an ideal choice to solvent-borne coating in case of interior wall coatings. Furthermore, growing commercial businesses are boosting the need for protective coatings aimed at asset protection against rust oxidation and corrosion. All these factors together are enhancing the adoption of UV-curable resins in coating applications.

APAC UV Curable Resins & Formulated Products Marketplace:

An increase in urbanization at a faster pace is influencing the rise in the number of automotive vehicles in the world. Therefore, coatings are used in large quantities to cope up with the escalating automotive production. The rapid expansion of the automotive and manufacturing industries in China and India are amplifying the necessity of coatings in the APAC region. Increment in automotive production of Indonesia from 1.1 million in 2016 to 1.2 million in 2017 is attributing the growth of the coatings market in this county. Hence, APAC held a dominating share of 43% among other regions in the global UV curable resins market during 2018.

UV Curable Resins & Formulated Products Market – Competitive Landscape

Arkema S.A., Allnex, Toagosei Co., Ltd., BASF SE, Koninklijke DSM N.V., Covestro AG, Nippon Gohsei Limited, Hitachi Chemical Company, Ltd., IGM Resins, and Miwon Specialty Chemical Co. Ltd. are noted as UV Curable Resins & Formulated Products top 10 companies, globally.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500160

Related Report:

- Epoxy Resin Market

https://www.industryarc.com/Report/16463/epoxy-resin-market.html

- UV Curing Resins Market

https://www.industryarc.com/Report/18629/uv-curing-resins-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id= 500160

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Polyurethane Composites Market is Augmenting Due to its Versatile Mechanical Properties in Automobile Industry

Polyurethane Composites Market: Transportation Industry Leaping Forward With Increasing Demand for PU

In-vehicle engineering, significant weight reductions are being achieved through the use of fiber-reinforced plastics. The OEMs are adopting versatile profitable, and simple processing along with unattainable individuality and functional integration with conventional materials. Polyurethane composites (PU) and carbon reinforcing fibers form of it - a prominent alternative used in the pultrusion industry, provide an exceptional way of exploiting the benefits of fiber-reinforced plastics. In the European Union, the transport sector is responsible for emitting one-third of total CO2 emission which is substantially growing. PU composites contribute through the reduction of material intensity via weather and corrosion resistance and high-performance coatings improving material durability. Rising adoption of PU in the end-use industries such as building & construction, transportation, wind power energy, and electric & electronics is propelling the growth of the polyurethane composites market in recent times. The transportation segment of the market is gaining profitable revenues with the development of lightweight automotive components. The segment is expected to increment at a notable CAGR of 10% during the forecast period 2019-2025 as the product has superior physical and mechanical properties competing with the other materials. Therefore, the PU composites’ versatility is highly instrumental in attaining the particular mechanical properties that are solely required for specific applications. Because of this, the demand for PU composites is driving the transportation industry growth.

As of 2018, the global polyurethane composites market size was evaluated to be $517 million. Moreover, the market is poised to grow at a CAGR of 6% during the forecast period 2019-2025.

Polyurethane Composites Market dominated by APAC

APAC held the largest regional revenue share in the polyurethane composites market of 46% in 2018. The growth is attributed to heavy investments in various application industries and a high economic growth rate. An increase in the disposable income, rise in population, and change in the lifestyle of the people in the region along with rising demand for polyurethane resin from the footwear and automobile industries is bolstering the polyurethane composites market share. In 2017, the automotive industry in China and India experienced a growth rate of 3.19% and 5.83% in terms of vehicle production respectively. In the recent era, the automotive and transportation industries have been growing at an adequate rate, especially in China and India, thereby creating noteworthy prospects. Furthermore, the government in APAC is taking several initiatives for improving the inflow of foreign direct investment in order to cater to the demand for PU composites in the domestic marketplace.

Major Frontrunners in the Market

The key companies dominating the global polyurethane composites market are BASF SE, SGL Group, Bayer AG, Owens Corning, Hexcel Corporation, Sekisui Chemical Co., Ltd., Huntsman Corporation, Wanhua Chemical Group Co., Ltd., The Dow Chemical Company, and Toray Industries.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500324

Related Reports:

- Medical Composites Market

https://www.industryarc.com/Report/16474/medical-composites-market.html

- Composites Materials Market

https://www.industryarc.com/Report/246/composite-materials-market-analysis-report.html

- Sports Composites Market

https://www.industryarc.com/Research/Sports-Composites-Market-Research-500420

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a proposal, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500324

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a research and consulting firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Glass Substrate Market Anticipated to Surge at a Notable CAGR of 9% During the Forecast Period 2019-2025

The glass substrate is a thin panel and key material used for LCDs. The essential entities of a glass substrate such as a polarizer, a color filter, and a liquid crystal layer, make it an ideal design choice for the electronics industry. The global electronics industry is flourishing with mounting demand for smart handheld devices, LCDs in consumer durables, semiconductors, and automotive applications. Subsequently, the global electronics industry generated a revenue of $4,216 billion through increased production in 2017. As a result, the electronics segment of the glass substrate market is anticipated to surge at a notable CAGR of 9% during the forecast period 2019-2025. Furthermore, the manufacturers of the glass substrate are continuously involved in the R&D to introduce varied product portfolio. In the marketplace, the major players are undergoing an emerging trend; the use of a structured glass substrate. This structured glass substrate provides highly versatile and accurate features. This trend will continue to drive demand for improved LCDs, enable new applications, and miniaturization of more precise electronics through structures and thinner glass or silicon wafers. Lately, SCHOTT AG introduced a FLEXINITY portfolio of high precision structured glass. The development of similar products in the market has increased the ability to meet the challenging demands of the upcoming years.

As of 2018, the global glass substrate market size reached a value of $1.6 billion. Likewise, the market revenue is experiencing an increase at a CAGR of 6% through to 2025.

APAC Obtains Dominance in the Glass Substrate Market

In 2018, APAC had a maximum glass substrate market share of 48% in 2017. The electronic sector of APAC was valued to have a market size of $3,128 billion in 2017, and China was the top producer that experienced an 8% growth in 2018. With the adoption of industrialization, urbanization, and the presence of numerous electronic and automotive manufacturers are the key reasons for the growth in the region. Additionally, in subtropical Hong Kong, the demand for glass substrate that has new heat-insulated coatings combined with cesium tungsten bronze and antimony-doped tin oxide has increased rapidly by the manufacturers in recent years. The thermal and daylighting performance of these glasses effectively reduces the solar heat gain while maintaining the indoor daylight illuminance at a high level. Similarly, the demand for ITO coated glass substrate (indium tin oxide) deposited in ITO film are rising owing to frequent use as anti-reflective and for electroluminescence, and LCDs. After an in-depth analysis by the researchers, they have found that these glass substrates are prominently used in Hong Kong to improve building energy efficiency in cooling. Therefore, the glass substrate market is witnessing a significant increase as the OEMs and the potential investors are investing in the end-user application industries.

Major Frontrunners in Glass Substrate Industry

Some of the global glass substrate market top 10 companies are The Tunghsu Group, Asahi Glass Co., Ltd, IRICO Group New Energy Company Limited, SCHOTT AG, OHARA Inc., Corning Inc., LG Chem Ltd., Nippon Sheet Glass, HOYA Corporation, and Plan Optik. Moreover, the glass substrate market report by IndustryARC provides vital statistics, information, trends, data, and competitive landscape in detail in this niche lucrative growing sector.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500139

Related Reports:

- Optical Coatings Market

https://industryarc.com/Report/15075/optical-coatings-market.html

- Advanced Glass Market

https://www.industryarc.com/Report/15105/advanced-glass-market.html

- Flat Glass Market

https://www.industryarc.com/Report/15857/flat-glass-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a proposal, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500139

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a research and consulting firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Increasing Adoption of Solar PV Glass in Building Facades Contributing to growth of Solar Photovoltaic Glass Market

Energy plays a vital role in determining the economic development and growth of a nation. Currently, there is an increase in demand for electricity to achieve rapid growth in the economy and to avoid the adverse effects on the environment due to unsustainable energy production. Solar energy is the most prolific method of energy capture in nature and a viable source of electricity, which leads to the invention of cost-effective solar cells. Thus, this energy is experiencing a notable acceptance at residential and commercial establishments as glass configuration PV panels have become a safer choice of integration in buildings. Because of this, it is estimated that solar energy delivers nearly 50% of the world’s energy by 2050 on its way to claim a dominating share of global power generation. It is possible through the performance improvement of solar glass and low Levelized Cost of Energy (LCOE). Thus, solar photovoltaic (PV) glass manufacturers are focused on designing a variety of solar PV glass and anti reflective coating glass combining high-performance space-grade solar cells to fulfill the need for more light in desired environments. Moreover, the increasing adoption of solar PV glass in building facades is contributing to an increment in the solar PV market size. This solar glass adoption defines the starring role of solar in the future powered with renewable energy, as it enables greater light penetration. Companies in the solar PV glass industry are focusing on anti-reflective coatings for solar PV glass, as it boosts up the performance in solar panels by 3% thereby increases the PV modules power output and also pull down the LCOE. Hence, it is enlarging the scope for the companies to increase their solar PV glass market share.

The global solar photovoltaic glass market size was evaluated at $4.5 billion in 2018, set to grow with a noteworthy CAGR of 28.65% all through the forecast period 2019-2025.

Utility Application Prevalence in the Solar PV Glass Market:

The utility application of the solar PV glass market is set to grow at the fastest CAGR of 32.56% among all other applications over the forecast period. Presently, most of the efficient solar panels are equipped with space-grade PV cells along with concentrated glass cover to overcome the drawback regarding the installation space requirement on both rooftop and land. For this, cost-effective solar PV glass is preferred to increase the efficiency and durability of solar panels. Additionally, it is easy to install on the rooftop and the ground as well. Global glass manufacturers aim to incorporate transparent solar power technology into architectural window glass allowing buildings to generate their onsite renewable energy as part of the building integrated photovoltaic (BIPV) market. BIPV products are the perfect suit to meet aesthetic demands and widely acceptable among architects, designers, and occupants. In addition to this, the glass maker’s effort to develop advanced architectural window glass products coupled with replacement of traditional building facades with power-generating glass is boosting the prominence of solar PV glass, a power-generating skyscraper in a utility application.

APAC Solar Photovoltaic Glass Marketplace:

APAC has established a dominating share of 39% in the global solar photovoltaic glass market revenue, as of 2018. An increase in the number of energy-guzzling buildings with solar PV glass in APAC coupled with the motto to maintain an energy-conscious environment to save resources is impacting architects to make more energy-efficient buildings in this region. Growing usage of clean energy to reduce hazard effects of carbon emissions on the environment is rising solar generation capacity in the Asian countries. Additionally, government policies and initiatives to ensure renewable energy generation supporting the installation of solar PV plants in eminent countries such as India and China of APAC.

Solar Photovoltaic Glass Market – Competitive Landscape

Xinyi Solar Holding Ltd., Nippon Sheet Glass Co. Ltd., Saint-Gobain S.A., Guardian Industries, Trina Solar Ltd., Asahi Glass Co. Ltd., Canadian Solar Inc., First Solar Inc., Yingli Green Energy Holding Company Ltd., ReneSola Ltd., Hanwha Q CELLS Co. Ltd., and Sun Power Corporation are competing to stand among Solar Photovoltaic Glass top 10 companies, globally.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500321

Related Report:

- Flat Glass Market

https://www.industryarc.com/Report/15857/flat-glass-market.html

- Automotive Solar Control Glass Market

https://www.industryarc.com/Report/18739/automotive-solar-control-glass-market.html

- Smart Windows Market

https://www.industryarc.com/Report/1258/smart-windows-market-analysis-report.html

- Nanotechnology Market

https://www.industryarc.com/Report/15022/nanotechnology-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500321

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Oxo Alcohol Market to Continue Harness Profits with Prolific Demands for Paints and Coatings

The oxo alcohol market is witnessing the extent of demands propelling from various end-user industries including oil & gas, automotive, pharmaceutical, textile, construction, and the chemical sector. Olefins are added to the hydroformylation reaction of carbon monoxide and hydrogen that results in the aldehyde. Further, the hydrogenation process is used on the aldehydes to form alcohols. The chemical processes involved are not limited to hydroformylation reaction only, but also extends to azeotropic distillation. The oxo alcohols are dehydrating agent that portray high demands owing to their application as solvents for preparing paints, plasticizers, coatings, lubricant additives, adhesives, and chemical manufacturing. The global demands in the oxo alcohols market generated revenues worth $8.2 billion in 2018. Foreseeing the heavy application of oxo alcohols in various end-user segments, the opportunities in the market are projected to grow at a CAGR of 3.5% during the forecast period 2019 to 2025.

North America: Most Lucrative Region in the Oxo Alcohols Market

The North American region was observed as the most productive region in the oxo alcohol market that acquired 33% of the total market share in 2018. These alcohols are an essential resource to manufacture polyvinyl chloride (PVC) products and the extensive demand for PVC plastics from the construction and the automotive industry is boosting the sales in the oxo alcohol market. Other than the plastic demands, the escalating demands for oxy alcohol byproducts from the paints and the coatings industry is one of the major reasons reflecting the heavy market share of North America. Considering the European region, the demands are sluggish due to global uncertainties such as the US-China trade war and Brexit that hindered the customer confidence in the market.

Additionally, the demands were also hampered due to stringent government policies in the region that portrayed the denial of plastic consumption in the region. However, APAC possesses a significant potential in the oxo alcohols market due to the growing indirect or direct demands from the flourishing construction and automotive industry.

Application Analysis in the Oxo Alcohols Market

Oxo alcohols have a range of applications such as plasticizers, acetate, solvents, lubricants, glycol ethers, and acrylates. Among these, the application of acrylates is poised to be the key application in the oxo alcohols market, also, the demand for this application is growing at a CAGR of 3.1% during the forecast period. Acrylates are mostly used for paintings, coatings, and adhesion applications. With growing paints and coatings demands in the constantly expanding construction, automotive, and the consumer electronics industry, the demands for acrylates are also incrementing that is further expected to benefit the global oxo alcohol market soon.

Oxo Alcohols Market Competitive Landscape

The companies influencing the oxo alcohols market are LG Chem, BAX Chemicals, Eastman Chemical Company, Dow Chemical Company, BASF Petronas, ExxonMobil Chemical Company, Qatar Petroleum, Andhra Petrochemicals, Arkema and Evonik Industries.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500319

Related Reports:

- a) Southeast Asia Propylene Market

https://www.industryarc.com/Report/15016/southeast-asia-propylene-market.html

- b) Alpha Olefin Market

https://www.industryarc.com/Report/15151/alpha-olefin-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

CFRTP Market estimated to increase at a CAGR of 9.3% for the period of 2019-2025

The prominence of lightweight materials such as CFRTP and Non-crimp fabrics (NCF) in a gamut of industries including automotive, especially for the energy-conservation factor, is creating a scenario of profitability in markets such as CFRTP market as the material is recognized as a lightweight innovation. This is predominantly evident in two industries namely automotive and aerospace wherein lightweight materials are replacing all the heavy materials for better fuel efficiency and the subsequent lesser CO2 emissions.

The CFRTP market size is also augmented due to the exuded demand from the consumer electronics sector as the material finds its application in laptops and mobile phones. Furthermore, the players are also acquiring some of the CFRTP market share from the wind energy sector as it is used in wind turbines.

In the wake of the growth of eco-friendly products, the companies are venturing into the industry and commencing new production units to acquire more CFRTP market. For instance, in March 2018, Covestro announced to begin the commercial production of CFRTP to leverage the potential arcade in the automotive and consumer electronics industry.

Made by direct resistance heating, CFRTP is also known for direct energization which makes it useful in the end-user industries. Furthermore, there has been research in progress for more applications. For instance, an isothermal forming system is recently developed in order to check CFRTP press forming behavior.

In the forthcoming years, more companies will strive to capitalize on the rising demand which had led to CFRTP market size of $750 million as of 2018, and it is poised to increment at a profitable CAGR of 9.3% during the forecast period 2019-2025.

The Potential for Profitability in the Automotive Application Segment of the CFRTP Market:

The total emission from the transportation sector was gauged at 6,457 million metric tons of CO2 equivalent, and the figure is poised to increase in the upcoming years due to the increasing usage of vehicles. However, reducing greenhouse emissions is one of the prime motives in the sustainable development goals (SDGs) by the United Nations (UN). Now, this is increasingly encouraging the automotive industry to take steps in order to reduce the CO2 emissions attributable to the transportation sector, which is paving path for the CFRTP market growth.

With 95.6 million vehicles manufactured in 2018, the automotive industry is on a path for further progress and the advent of the autonomous vehicles will further support the growth of the associated market. Resultantly, the application of CFRTP in the automotive industry will increase at a CAGR of 7.82% through to 2025.

APAC Experienced Maximum CFRTP Market Share of 34% in 2018:

The booming Chinese automotive industry is found to be one of the most effective factors for the CFRTP market growth prospects in APAC. The Chinese automotive witnessed sales of over 27 million vehicles in 2018, the government expects the output to reach 30 million units by 2030, which will further create opportunities for the CFRTP market players in China.

Furthermore, Indian automotive industry became the fourth largest in the world with 9.5% year on year increase in sales in 2017 with 4.02 million units sold during the year. Indian automotive industry is on the path of growth and the upcoming years have more opportunities for the CFRTP market players in the same.

Top 10 CFRTP Market Companies:

The companies with maximum CFRTP market share that are expanding through geographies are Aerosud, SGL Carbon SE, Royal Ten Cate (TenCate), PolyOne Corporation, Toray Industries, Inc., Covestro AG, and Solvay S.A.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500322

Related Reports:

- CFRP & CFRTP for Prosthetics & Orthotics Market

https://www.industryarc.com/Research/CFRP-CFRTP-For-Prosthetics-And-Orthotics-Market-Research-501940

- Composites Market

https://www.industryarc.com/Report/15225/composites-market.html

- Automotive Carbon Thermoplastic Market

https://www.industryarc.com/Research/Automotive-Carbon-Thermoplastic-Market-Research-500231

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500296

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Unceasing Demand for Long Fiber Thermoplastics From the Automotive Industry Driving the Growth of Long Fiber Thermoplastics Market

Innovations in the arena of chemicals and materials has resolved several operational and environmental issues faced by various sectors. For instance, with the advent of thermoplastic, the automotive sector which is trying to implement the trend of ‘low carbon economy’ has overcome the complexity of reducing vehicles weight to enhance fuel efficiency. And in the flourishing construction sector that is moving towards the trend of ‘skyscrapers’, ‘energy efficient structures’, and ‘intricate designs’, thermoplastics finds ample scope of application owing to its thermal insulation properties. As a consequence, the long fiber thermoplastic (LFT) market companies is leveraging the dire need of industries relying on LFT seeking metal replacement applications and semi-structural applications. Moreover, as electric vehicles is the asylum sought by the global automotive sector to diminish its participation in ‘carbon footprints’, LFTs are being commoditized as they are extensively employed in such weight-centric vehicles designing and manufacturing. The pacing EVs market is adding substantial impetus to the global LFT market demand.

Hence, the global long fiber thermoplastic (LFT) market size was evaluated to be $1.1 billion in 2018. Injection molding is used with inline compounded material that virtues thermal isolation and creep resistance. The trend of hybrid LFTs is pacing up as they offer high performance at low cost by blending carbon fibers with other fiber reinforcements such as glass fibers via injection molding. Moreover, this combination of glass and fiber also reduces the overall weight, the most sought after resolution by LFT market end-user industries such as automotive, construction, and electronics. This trend is estimated to be the most disruptive force, catapulting the market to grow at a global CAGR of 5.8% during the forecast period of 2019 – 2025.

APAC leads the global long fiber thermoplastic (LFT) demand as India and China pace up their ‘electric mobility’:

APAC is reckoned to be the leading region globally in terms of LFT market size, as the region in 2018 generated 44% of the global demand share. This lucrative trade in APAC is attributable to the strong presence of globally leading automotive manufacturers in India, China, and Japan, and the flourishing construction and electronics industry in similar economies.

Some facts supporting the argument -

The trend of electric vehicles in the automotive sector in APAC is adding impetus to its long fiber thermoplastics market. In 2018, the global electric car fleet exceeded 5.1 million units with China alone witnessing sales of nearly 1.1 million units. And the country also led the global electric car stock with 2.3 million (approximately 50%) units. By 2030, China and Japan are estimated to secure 1st and 3rd position in global EV market respectively. Not just EVs, even the contemporary ICE engine vehicles manufacturers are implementing ‘light weight design’ to enhance fuel efficiency of vehicles. The overall automotive market in APAC is flourishing as well with growth rate in India (+7.98%), Indonesia (+10.31%), and Malaysia (+12.18%).

By 2030 the global volume of construction output is estimated to grow by 85% to $15.5 trillion. China, United States, and India are forecast to account for 57% of this global growth. Likewise, India is estimated to develop twice as faster as China. This humongous growth in the global as well as APAC’s construction sector is playing a vital role in LFT market growth.

The unceasing demand for long fiber thermoplastics generated from the automotive industry is recognized as a significant influence contributing towards the growth of the global long fiber thermoplastics market. The automotive industry is identified as the fastest growing application segment, proceeding with an application CAGR of 4.1% during the forecast period of 2019 – 2025. Long fiber thermoplastics (LFTs) are extensively used as replacements for conventional materials such as metal assemblies, die castings, and underperforming plastics in the automotive industry. They are lightweight and enhance the performance, dimensional stability, and strength of the automobile and hence improve the fuel efficiency to meet the quality standards set by regulatory bodies. This inexpensive innovative material also assist in help in lowering the automotive manufacturing cost.

Long Fiber Thermoplastics (LFT) Market Companies:

Some of the key players with majority of the global long fiber thermoplastics market share are Polyone Corporation, Plasticomp, Inc., SGL group, RTP Company, Sumitomo Bakelite Company Limited, TechnoCompound GmbH, Daicel Polymer Ltd, Inc, SKYi innovations, Inc, Great Resins Industrial Co, Inc, Celanese, Inc., Quadrant Plastic Composites (Schweiz) AG, Solvay Inc, Asahi Kasei, Inc, Lanxess, and SABIC.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500317

Related Reports:

- Thermoplastic Composites Market

https://www.industryarc.com/Research/Thermoplastic-Composites-Market-Research-502955

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500317

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

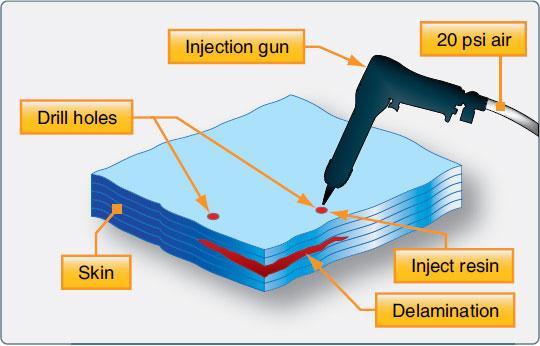

Composite Repairs Market to Witness Stellar Growth with Increase in Renovation and Restoration of Old Structures in the Construction Industry

The global composite repairs market witnessing a propelled growth, owing to the rise in renovation and restoration of hoary structures, and cost-saving associated with these repairs. The construction sector across the globe is anticipated to grow $8 trillion by 2030. The rapid growth in the construction industry, which in turn, impels the composite repairs market share globally. Furthermore, fibreglass resin, carbon fiber reinforced and wood plastic composites damages are best determined for structural components using suitable Non Destructive Tests (NDT). Automation of composite repair is the key factor fueling the growth of the composite repairs market. Therefore, automation in this process minimizes total time consumption in composite repairs, thereby its market growth in the upcoming years.

The global composite repairs market size attained a value of $10.1 billion in 2018 and is expected to grow with a CAGR of 8.2% throughout the forecast period 2019-2025.

Lightweight Vehicle Trend in the Automobile Industry Showing Positive Impact on the Composite Repairs Market Growth

The automotive sector around the globe is trying out to implement a new type of composite material to reduce the weight of automotive so that it can be more fuel-efficient, such manufacturing of automotive will fuel the inclusion of composite repairs in the manufacturing process to detect and eliminate various faults. The number of lightweight vehicles produced worldwide was around 19.5 million in 2017 and it reached around 20.6 million in 2018. Electric vehicle’s body frame manufacturing companies are another major consumer of composite repairs.

Asia-Pacific Held Major Share of the Composite Repairs Market

Asia-Pacific generated 42% of the global composite repairs market revenue in 2018. Growing commercial aircraft fleet, indigenous production of commercial and regional aircraft, the opening of assembly plants in China by major commercial aircraft OEMs such as Boeing and Airbus, and increasing aircraft maintenance activities are the major factors for the growth of the composite repairs market in Asia-Pacific region. NDT method is performed to identify the damages in the composite structures in aircraft. Factors such as the growing demand for new aircraft to cater to the increasing air passenger traffic in emerging economies such as China and India are driving the composite repairs market in this region.

Lucrative Demand for Composite Repairs in the Aerospace & Defense Sector

The application segment that will be creating the most lucrative opportunities for the composite repairs market is the aerospace and defense sector. This application segment is projected to grow at a CAGR of 6.89% through to 2025. Increasing penetration of composites in next-generation aircraft, such as Boeing 787 Dreamliner in which 50% of its weight constitutes composite materials, is creating a substantial demand for composite repairs market growth in the upcoming years. The reduced airframe weight enables a better fuel economy and, therefore, lowers operating costs. Thus, the rising air traffic in the Asia-Pacific region is another factor to spur the demand for commercial and passenger aircraft thereby composite repairs market.

The Major Players in the Composite Repairs Market:

Prominent players in the composite repairs market include Hexcel Corporation, Gurit Holding, The 3M Company, Henkel AG & Co. KGaA, Sherwin-Williams Company, Heatcon Composite Systems, and WichiTech Industries Inc.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500312

Related Reports:

- Composites Market

https://www.industryarc.com/Report/15225/composites-market.html

- Aerospace Composites Market

https://www.industryarc.com/Report/16454/aerospace-composites-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500312

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Vapor Recovery Units Market Gaining Leverage From The Oil and Gas Industry For Insinuating Growth

The vapor recovery units market will be positively impacted by government regulations on reducing vapor toxicity in the atmosphere during the forecast period. Every time a fuel tank is filled or an operation is carried out at an oil and gas factory, toxic gasoline vapors are released into the atmosphere. This has made governments across the world intervene and instigate the installation of vapor recovery units across all manufacturing units. For example, the United States has been estimated to consume 392 million gallons of motor gasoline daily in 2018. This has caused an unprecedented release of vapor into the atmosphere, thus increasing environmental toxicity. To combat this, the USA government has passed the Clean Air Act in 1970 which has undergone several amendments since then. The Act has been successful in removing atmospheric toxicity by implementing regulations such as the removal of leaded gasoline in vehicles. The vapor recovery units market size was valued at $801 million in 2018. The vapor recovery units market share has been further estimated to grow with a CAGR of 4.5% during the forecast period 2019-2025. Some of the vapor recovery units include soxhlet extraction, reciprocating compressor, rotary screw compressor, and rotary vane compressor.

Europe Emerging As The Geographical Leader Of The Vapor Recovery Units Market

On the basis of region, Europe has emerged as the geographical leader of the vapor recovery units market. The region held a 34% share of the total revenue earned by the market in 2018. In July 1993, the European Union Commission, headquartered in Brussels prepared and released a draft directive on vapor recovery in the continent. The directive divided vapor recovery into two phases of stages, in which Stage II has played a key role in further shaping of independent vapor recovery regulations of European countries. Europe has been remarkable in replacing passive Stage II systems with active systems, thus further incrementing the growth of the vapor recovery units market in this region.

Vapor Recovery Units Market’s Most Promising Segment Is Oil and Gas Industry

On the basis of end-use industry, the vapor recovery units market will be segmented into oil and gas, landfill, petrochemicals, pharmaceuticals, and others. The oil and gas industry has emerged as the most favorable segment of the market. Refining of crude oil and liquefied petroleum gas is carried out routinely at oil and gas manufacturing units. It is therefore essential for vapor recovery units to be installed in order to minimize the unnecessary release of toxic gasoline vapors into the atmosphere. Gasoline stations are also now equipped with vapor recovery units for reducing vapor release in the atmosphere while customers fill their vehicles with the required fuel. These factors have been pivotal in making the oil and gas segment the most important for this market. This application segment will grow with a CAGR of 3.2% during the forecast period 2019-2025.

Vapor Recovery Units Market: Key Players

Companies that have made a noticeable impact in accentuating the growth of the vapor recovery units market are Carbovac, BORSIG Membrane Technology, John Zink Company, SYMEX Technologies, Aereon, HY-BON/EDI, Cool Sorption, VOCZero, Zeeco, Flogistix, Kappa Gi, and Kilburn Engineering.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500309

Related Reports:

Vapor Deposition Market

https://www.industryarc.com/Report/16437/vapor-deposition-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500309

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Heat Resistant Polymers Market Leveraging the Automotive Transition towards Lightweight Vehicles

In the contemporary era, wherein the end-use industries such as automotive, aerospace, electrical, and electronics are accelerating at a fast pace, there is a trending transition from the usage of conventional materials such as metals and ceramics to lightweight plastics. So, the heat resistant polymers such as fluoropolymers, polyphenylene sulfides, polyether ether ketones, and polyimides are enticing significant interest in multifarious industrial applications as they are light in weight and resistant to degradation at high temperatures. Aerospace and automotive manufacturing companies are continuously engaged in the adoption of lightweight plastics to decrease the overall weight of the vehicle, eventually to increase the fuel efficiency of the vehicle. Moreover, the fuel systems engine components, coolant systems, sockets, transmission components, and brake systems, which are exposed to higher temperatures and harsh environments, can be manufactured using the aforementioned polymers. Therefore, the incessantly increasing demand for heat resistant and lightweight polymers in the automotive and aerospace industries is considered to be the prime factor for the growth of the heat resistant polymers market. Additionally, the tremendously increasing number of automobiles and aeroplanes across the world will obviously foster the growth of the market. For instance, the airline industry will need more than 44,000 new commercial aeroplanes by 2038.

The heat resistant polymers market was valued at $11 billion in 2018. Furthermore, the demand for heat resistant polymers is poised to propel at a CAGR of 7.2% during the forecast period 2019-2025.

Asia-Pacific Region Providing Promising Prospects for Heat Resistant Market Growth—

Geographically, the Asia-Pacific region is anticipated to provide promising growth prospects for the heat resistant polymers market during the forecast period and was responsible for 42% of the total revenues generated in 2018. The emergence of this region as the lucrative marketplace can be attributed to the presence of emerging economies such as India, Japan, and China. These countries are experiencing tremendous growth in the industrial sector due to the emergence of Industry 4.0 and technological advancements. The increasing demand for heat resistant polymers from the booming end-use industries such as automotive, electronics, and transportation in these countries is responsible for the regional market growth.

Transportation Sector Surfaces as a Key Application Segment in the Heat Resistant Polymers Market—

On the basis of the end-use industry, the transportation sector is considered to be the key application segment in the heat resistant market, which is anticipated to grow at the highest rate during the forecast period. The dominance of this segment is attributed to the growing popularity of vehicles that are comparatively light, compact, and fuel-efficient. Stringent governmental regulatory frameworks pertaining to CO2 emissions and concerns regarding fuel efficiency have compelled manufacturers concerning the transportation sector to develop lightweight vehicles, thereby propelling the demand for lightweight materials. As of 2018, transportation activities are accountable for 24% of direct CO2 emissions from fuel combustion. Moreover, road transport responsible for 75% of the overall emissions produced by the transport sector. Such festering figures has initiated the usage of lightweight materials to decrease the overall weight of vehicles, which is a major factor driving the growth of the heat resistant polymers market. Therefore, the key application segment is projected to prosper at a CAGR of 6.4% through to 2025.

Heat Resistant Polymers Market Companies’ Strategies—

Some of the key players in the heat resistant polymers market are Honeywell International, BASF SE, DuPont de Nemours, Inc., Daikin Industries, Ltd., DIC Corporation, Evonik Industries AG, Celanese Corporation, Solvay S.A., PolyOne Corporation, RTP Company, and Tri-Mack Plastics Manufacturing Corporation. These companies are adopting business strategies such as new product launches, expansions, acquisitions, mergers, partnerships, agreements, and joint ventures, to achieve sustainable growth in the global heat resistant polymers market.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id= 500297

Related Reports:

- High Performance Polymers Market

https://www.industryarc.com/Report/11659/high-performance-polymers-market.html

- Flame Retardant Chemicals Market

https://www.industryarc.com/Report/11692/flame-retardant-chemicals-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500297

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Ceiling Tiles Market poised to increment at a healthy CAGR of 9.1% during the forecast period 2019-2025

With the increasing emphasis on décor and environmental factors that include VOC emissions and energy consumption, ceiling panels or ceiling tiles have become an integral part of the modern construction industry. Tin ceiling tiles, even though they are expensive, have paved their way into the commercial sector wherein the property owners strive for a greener architecture in order to improve energy efficiency. These acoustic ceiling tiles and plastic ceiling tiles are also known to instill aesthetics in the interior of a building. Heavily adopted by corporate offices and malls, the ceiling tiles market is proving to be a lucrative business in the contemporary real estate industry.

As of 2018, the ceiling tiles market size was gauged at $5.1 billion, and it is poised to increment at a healthy CAGR of 9.1% during the forecast period 2019-2025.

North America Dominated the Ceiling Tiles Market in 2018:

The growth of the ceiling tiles market can be largely attributable to the growth of the real estate sector worldwide, especially in developing countries such as China and India wherein the emerging housing requirement is catapulting construction activities. However, North America was positioned as the maximum ceiling tiles market share bearer in 2018 with 33% in global revenues.

While the greater share is because of the increasing real estate and reconstruction projects in the residential sector of the US, Mexico, and Canada, the big pocket customers from the commercial sectors offered lucrative opportunities to the players. Rockfon (Rockwool Group) identified the possibilities for revenue sources in the North America ceiling tiles market in 2017 begun the production in its regional production facility in July 2017, which significantly uplifted the region’s ceiling tiles market share in 2018.

The Most Gainful Ceiling Tiles Marketplace – Non-Residential Buildings:

The application ceiling tiles in non-residential buildings will increase at a CAGR of 6.58% through to 2025. This is attributable to the fact that non-residential buildings such as offices, malls, and other complexes invest relatively higher sum of money than the residential real estate. The energy consumption attributable to buildings was evaluated at 3,060 Mtoe in 2018 – a significant fraction of which is because of the increasing number of commercial buildings. With the current boom in the non-residential real estate, the figure is poised to increase further. In order to ameliorate this, the owners would be required to use greener products in the interiors. Ceiling tiles instill higher energy-efficiency due to their daylight efficacy and thermal insulating qualities, and therefore, they are preferred in the buildings.

The Future Scenario for the Ceiling Tiles Market:

The global construction market is projected to growth exponentially and attain a valuation of $8 trillion by 2030 in which China, India, and the US will play a major role. This growth resonates with the increasing housing requirements, infrastructural demand, and the commercial building boom, which will create lucrative opportunities for the ceiling tiles market players.

To sum it up, the current lucrative regime of the real estate and the need for sustainability in the buildings will produce a lot of opportunities for the players competing for ceiling tiles market share.

Top 10 Ceiling Tiles Market Companies:

The companies crusading for greater ceiling tiles market share and position themselves in the industry are USG Corporation, Armstrong World Industries, Inc., SAS International, Hunter Douglas N.V., Rockfon (The Rockwell Group), CertainTeed Corporation, Knauf Gips KG, Gyproc Saint- Gobain Gypsum, Odenwald Faserplattenwerk GmbH, and Georgia-Pacific LLC.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500296

Related Reports:

- Lubricants Market

https://www.industryarc.com/Report/11709/lubricants-market-analysis.html

- Lubricant Additives Market

https://www.industryarc.com/Report/11708/lubricant-additives-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500296

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Polyarylsulfone Market Experiencing Propitious Prospects in the Healthcare Industry

With the enormous opportunities offered by the automotive industry, polyarylsulfone market is experiencing exuded profitability and more so when the augmenting number of vehicles produced is increasing the polyarylsulfone market size. On the other hand, the hydrolysis stability make polyarylsulfone a useful material in medical applications that involve autoclave and steam sterilization. The application of this high-performance thermoplastics in the healthcare industry is further creating a demand influx in the polyarylsulfone market, and therefore, the companies are striving to expand their geographic territories in order to gain maximum polyarylsulfone market share across the globe. For instance, in October 2017, Solvay S.A. expanded its production capacity of sulfone polymers that included polyarylsulfone. BASF SE also identified the increasing polyarylsulfone market demand and started a polysulfone production line in Korea in April 2018.

The material is also emerging out to be a better alternative to polypropylene and polyamide because of which it is getting traction from the aforementioned end-user industries. Polyarylsulfones are also sometimes blended with polyvinyl chloride for the removal of heavy metals such as Cadmium, Chromium, and Lead. Another application of polyarylsulfone gaining prominence is the gas separation as the polysulfone membranes containing magnesium oxide impart better performance during separation.

The increasing applications are enhancing the polyarylsulfone market demand across industries. As of 2018, the polyarylsulfone market size was gauged at $1.8 billion, and it is projected to increase at a CAGR of 8.1% during the forecast period 2019-2025.

Healthcare Industry – A Profitable Polyarylsulfone Marketplace in the Upcoming Years:

The application of polyarylsulfone in the healthcare industry is estimated to escalate at a CAGR of 6.24% through to 2025. While the growth is attributable to the merit of the material for the applications that require high-strength polymers, the demand is also because of the growth of the healthcare industry worldwide, especially in developing countries. Polyarylsulfones are used in steam sterilization of reusable medical devices as they are resistant to the degradation from water. For instance, endoscopes are reusable and polyarylsulfone is utilized for their steam sterilization for reuse. Now, with the booming endoscopy devices market that attained a valuation of $11.4 billion in 2018 and it going to expand at a CAGR of 6.43% through to 2025, the polyarylsulfone market size is poised to increase in the aforementioned application segment.

Owing to the profitable prospects in the North American healthcare industry, especially in the US, the region had the maximum polyarylsulfone market share of 31% in 2018. The greater North America polyarylsulfone market share also resonates with the fact that the region had the maximum endoscopy devices market share of 54% in the global revenues. The upcoming years foresee rapid development of the US healthcare industry, which will impact the reusable medical devices market. Subsequently, the players will be targeting the US healthcare industry in order to gain more polyarylsulfone market share over the forecast period.

Polysulfone Market Companies –

The companies with the highest polyarylsulfone market share striving to thrive on the increasing demand from the healthcare, automotive, and other end-user industries are BASF SE, Solvay S.A., Sumitomo Chemical Co., Ltd., SABIC, Quadrant Engineering Plastics Product, NYTEF Plastics Ltd., Polymer Dynamix, RTP Company, Westlake Plastics Company, and The Ensinger Group.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500299

Related Reports:

- A. Polypropylene (PP) Resin Market

https://www.industryarc.com/Report/1295/polypropylene-resin-market-analysis.html

- Polymers Market

https://www.industryarc.com/Report/18767/polymers-market

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500299

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Rising Commercial Aircraft Production Attributed to the Amplified Demand for Carbon Fiber Prepreg Market

The global carbon fiber prepreg market size was $6.4 billion in 2018 and it is projected to grow at a profitable CAGR of 8.96% during the forecast period 2019 to 2025. This market growth is attributed to the amplified demand for carbon fiber prepreg from the rising commercial aircraft production and emerging electric vehicle market. The most common prepregs are manufactured using glass fiber, carbon fiber, and aramid fibers and these are based on the epoxy resins and vinyl ester. The heavy demand for strengthened carbon fiber prepreg is being witnessed from all over the globe due to its varied application in the automotive, aerospace & defense, construction, and consumer electronics industry.

Europe: Major Market Demands

The European region was concluded as the most profitable region with the carbon fiber prepreg market share of 33% in global revenues during 2018. The massive market share is resonated owing to the large presence of aircraft manufacturers, vast offshore renewable energy infrastructure, and electric car manufacturers. The APAC region closely follows the multiplying market demands in the European region. Foreseeing the consistently growing demands for electric mobility and renewable energy, the opportunities in the carbon fiber prepreg market in the APAC region are also projected to grow. Moreover, the opportunities in the carbon fiber prepreg market are supported by government policies that endorse the integration of electric vehicles and renewable energy.

Aerospace & Defense Application in the Carbon Fiber Prepreg Market

Carbon fiber prepreg is used in several end-user industries such as automotive, renewable, and construction industry. However, the utility of carbon fiber prepreg in the aerospace & defense sector is observed as the key application in the global carbon fiber prepreg market and the demands in the same are expected to flourish at a CAGR of 7.56% during the forecast period. This element possesses demand in the aerospace & defense industry owing to its features such as resistance to heat, resistance to corrosion, resistance to moisture, high strength-to-weight ratio, robust durability, and less maintenance. The volume of air passengers is growing at a significant pace today, the global air passenger volume is expected to reach $8.2 billion by 2037. This implicates the increased prospects for the production of commercial aircraft which will further induce demands in the global carbon fiber prepreg market.

Carbon Fiber Prepreg Market Competitive Landscape

The companies influencing the carbon fiber prepreg market are SGL Group, Gurit Holdings AG, Park Electrochemical Corporation, Toray Industries, Teijin Limited, Royal TenCate N.V. , Hexcel Corporation, Solvay, Mitsubishi Rayon Co. Ltd., Axiom Materials.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500300

Related Reports:

- a)Photoelectric Sensors Market

https://www.industryarc.com/Research/Carbon-Fiber-Resin-Market-Research-500423

- b)Pre-preg Market

https://www.industryarc.com/Report/15250/prepreg-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500300

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Chloromethanes Market Projected to Grow Due to its Wide Adoption in the Automotive and Pharmaceutical Industries

Increasing usage of chloromethanes in plastic manufacturing is estimated to surge its demand in the upcoming years globally. In 2018, the global trade of plastics and its related products was valued at around $655.79 billion. The growing trade of plastics, which in turn, incite the chloromethanes market growth. Chloromethane is an organohalogen, which is a crucial reagent in industrial chemistry. Owing to its use as an extracting agent in oils, resins, and gases, chloromethane which is also known as methyl chloride is preferred over other haloalkanes.

The global chloromethanes market size was valued at $1.9 billion as of 2018 and is expected to grow with a CAGR of 4.9% throughout the forecast period 2019-2025.

Proliferated Demand of Chloromethanes in the Automotive Industry

Chloromethane is used in silicone polymer production which has diverse end-use applications in the automotive industry. The number of motor vehicles produced worldwide is around 95 billion in 2018. Thus, increasing motor vehicle production in the automobile industry is directly proportional to the growth of the chloromethanes market across the globe.

Asia-Pacific Held Major Share of the Chloromethanes Market

Asia-Pacific generated 36% of the global chloromethanes market revenue in 2018. Chloromethanes intermediates such as silicone and fluoropolymers are important raw materials in the construction industry. Rapid urbanization in developing countries such as China and India is the primary factor influencing the growth of the construction sector, which in turn, spur the growth of the chloromethanes market in this region. India has a requirement of investment worth $773.73 billion in infrastructure by 2022. The increasing impetus to develop infrastructure in the country, which in turn, incites the usage of chloromethanes thereby its market value in this region. In India, government initiatives such as ‘Housing For All’ and ‘Smart City Mission’ are directing the progression of the construction sector which is further boosting the growth of the APAC chloromethanes market.

Lucrative Demand for Chloromethanes in the Pharmaceutical Sector

The application segment that will be creating the most lucrative opportunities for the chloromethanes market is the pharmaceutical sector. This application segment is projected to grow at a CAGR of 4.12% through to 2025. The extensive usage of chloromethane as a local anesthetic and as an intermediate material in drug manufacturing is anticipated to impel the demand for this market. Local anesthetics numb a particular part of the body, thus allowing the patient to be awake during surgery without feeling the pain. Also, methyl chloride is widely used as a raw material for cellulose ether which is significantly used as thickeners and binders in pharmaceuticals. Thus, the extensive use of chloromethane intermediates in the pharmaceutical sector is directly fueling the growth of the chloromethanes market.

The Major Players in the Chloromethanes Market:

Prominent players in the chloromethanes market include AkzoNobel N.V., Dow Chemical Company, Gujarat Alkalies & Chemicals Ltd., Ineos, Kem One, Occidental Chemical Corporation, Solvay S.A., Shin-Etsu Chemical Co., Ltd., and Tokuyama Corporation.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500302

Related Reports:

- Methylene Chloride Market

https://www.industryarc.com/Report/16167/methylene-chloride-market.html

- ChloroformMarket

https://www.industryarc.com/Report/17691/chloroform-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500302

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Magnesium Alloys Market Crafting Lightweight Solutions Reigning the Transportation Sector

Magnesium is the lightest element of all metal structures. This fundamental characteristic of magnesium alloy, in the form of magnesium wrought alloy or magnox, makes it an ideal design choice for the transportation industry. The global transportation industry is thriving with the demand for lightweight materials. Subsequently, the global light commercial vehicle production has increased by 5.9% during 2017-2018. Furthermore, a lightweight vehicle is a sustainable solution for environmental necessities to curb air pollution and reduce fuel consumption. These environmental demands are paving the way to extensive technological innovations in order to manufacture lightweight structures. Thus, these ecological aspects are linked to the usage of magnesium alloys in the transportation sector which enable low costs, recyclability, deformation strength, and impact safety. Along with that, magnesium is easy to weld, cast and forge, thereby making it easy to exist with other wrought alloys. As a result, the weight reduction achieved by the magnesium alloys without compromising its overall strength is surging the magnesium alloys market demand in transportation and other end-user industries.

The global magnesium alloys market size reached a value of $1.3 billion in 2018. Furthermore, the revenue is experiencing an uptick rising at a CAGR of 13.1% during the forecast period 2019-2025.

Magnesium Alloys Market Size Surging with the Environmental Initiatives Redefining APAC Automotive Sector

APAC dominated with magnesium alloys market share of 34% as of 2018. The rising demand for fuel efficiency in the automotive sector coupled with the environmental initiatives is boosting the magnesium alloys market demand in APAC. APAC countries such as China, India, and Japan are powerhouses for the automotive industry. In 2017-2018, China, India, and Japan experienced a huge growth rate in the production of lightweight vehicles with about 12.6%, 31.5%, and 3.4% respectively. Therefore, this increasing demand for lightweight vehicles is boosting the magnesium alloys market growth in these countries.

On the other hand, with the rapid surge of industrialization in APAC countries such as India and China, their environmental challenges are also reaching a tipping point. These problems are recognized and addressed by their governments by amending stringent environmental policies in diverse arenas. These green initiatives such as China’s recent (13th) five-year plan are spurring investments by implementing the strategic top-down approach in the automotive sector to curb air pollution. Thus, these endeavors are collectively boosting the demand for the magnesium alloys market in the automotive sector of APAC. As a result, the APAC magnesium alloys market is surging in the global marketplace.

Magnesium Alloys Market Offering Corrosion Resistance and Lift-off Weight Reduction in the Aerospace and Defense Vertical

Based on the end-user industry, the aerospace and defense segment is surging with ample opportunities in the global magnesium alloys market and rising at a CAGR of around 8.96% through to 2025. Dramatic improvements in the mechanical properties combined with superior corrosion resistance demonstrated by die-cast magnesium ensure high performance in aerospace and defense applications. In commercial and military aircraft, magnesium cast alloys reduce emissions and aid projectiles by increasing fuel efficiency. Furthermore, space crafts and missiles contain magnesium alloys to endure extreme operational conditions. Besides, magnesium ensures lift-off weight reduction which is of huge significance in flight dynamics. Also, innovations in aerospace are rising to increase the addition of magnesium in surface protection systems to avoid corrosion and flammability. As a result, these cutting-edge applications in the aerospace and defense industry is surging the growth of the magnesium alloys market.

Global Magnesium Alloys Top 10 Companies -

Companies such as Elektron, Ka Shui International Holdings Ltd., Magontec, US Magnesium LLC, Nanjing Yunhai Special Metals Co. Ltd., and Meridian Lightweight Technologies are leading the global magnesium alloys industry. Recent developments such as expansions, acquisitions, new product launches, and partnerships are increasing the revenue of these major stakeholders in the magnesium alloys industry.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500295

Related Reports:

a) Magnesium Metal Market

https://www.industryarc.com/Report/16106/magnesium-metal-market.html

b) High Performance Alloys Market

https://www.industryarc.com/Report/15512/high-performance-alloys-market.html

Any other custom requirements can be discussed with our team, drop an e-mail to sales@industryarc.com to discuss more about our consulting services.

To request for a quote, provide your details in the below link:

https://www.industryarc.com/reports/request-quote?id=500295

Media Contact:

Mr. Venkat Reddy

Sales Manager

Email: sales@industryarc.com

Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC: IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food and Beverages, Information Technology, and Life sciences and Healthcare.

Composite Doors & Windows Market Holding High Potential for Growth with the Rising Construction of Buildings

Exceptional properties of the composite materials such as corrosion, temperature, and chemical resistance, termite free, dustproof, and sound insulation, is the prime factor creating unprecedented demand in the composite doors market. Composite doors such as uPVC doors, double glazed doors, and PVCu doors are lightweight, maintenance-free, and are highly durable. Therefore, the need to replace wood and metal doors with superior quality, energy-efficient and aesthetically good looking doors without compromising on safety and performance, in the residential as well as industrial applications is driving the growth of the composite doors market. Moreover, on the back of demographic growth, the 55% of the world population currently resides in urban areas and it is expected to reach 68% by 2050, which means additional 2.5 billion people moving to urban areas. With the rising urbanization and rapidly expanding population, the construction activities in residential as well as commercial infrastructure are anticipated to grow at an alluring rate, which in turn is expected to fuel the composite doors and composite windows market demand. For instance, the Indian construction sector is projected to prosper at a CAGR of 15.7% to attain $738.5 billion by 2022.

As of 2018, the composite doors market was valued at $876 million. Moreover, the demand for composite doors and composite windows is projected to propel at a CAGR of 6.1% during the forecast period 2019-2025.

North America Domineering Composite Doors & Windows Market—

On the basis of the region, North America held the majority share in the global composite doors and composite windows market with a maximum revenue share of 33.3% in 2018. The dominance of the region is largely attributed to the growth in the residential and industrial construction and renovation activities in the developed countries such as the USA and Canada. For instance, the private housing completions in the USA reached 1,294,000 in August 2019, an increase of 5.0% from August 2018. Moreover, the presence of prominent market players such as Special-lite Inc., Curries Assa Abloy Group, Andersen Corporation, and Pella Corporation has positively influenced the growth of the composite doors market in North America.

Industrial Sector Surfaces as the Key Application Segment in the Composite Doors & Windows Market—

The industrial segment is considered to be the key application segment in the composite doors market that is anticipated to progress at the highest growth rate during the forecast period. The dominance of the segment is mainly due to the increasing demand for maintenance-free, corrosion resistant, and high chemical resistant doors in various industries. Moreover, the composite doors and composite windows are gaining significant popularity as they act as durable insulators and have the ability to maintain temperature inside the premises and provide dimensional stability. Therefore, the key application segment is presumed to proliferate at a CAGR of 5.8% through to 2025.

Composite Doors & Windows Market Companies’ Strategies—